The history of the crown cork (crown cap)

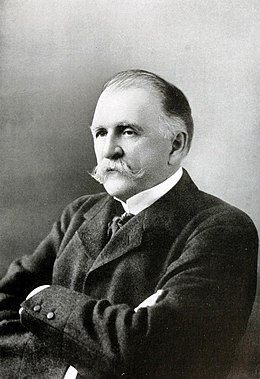

William Painter, an Irish-born American, invented the crown cork (original name) for bottled carbonated beverages in 1891 and obtained patents for it in February 1892.

Since the 1880s, carbonated drinks, available mainly in drugstores and pubs, were becoming increasingly popular, but those who wanted to take these bubbly drinks home with them were facing a major problem.

The stoppers used in most glass bottles at the time, which were typically made of metal, cork or porcelain, did not provide a sufficient seal to keep in the carbon

dioxide that created the drinks’ bubbles. Or worse, if they made contact with the bottles’ contents, they would make the liquid toxic, and thus, undrinkable.

Thanks to this invention, the problem of preserving carbonated drinks is completely solved.

The other advantage over the cork stoppers ![]() that existed at the time was that the bottles could now be stored upright instead of lying down so that the cork remained in contact with the liquid.

that existed at the time was that the bottles could now be stored upright instead of lying down so that the cork remained in contact with the liquid.

He founded in 1892 his own manufacturing business, the Bottle Seal Company, in Baltimore and approached not only soft drink manufacturers but also brewers.

Due to the almost immediate success of the Crown Cork he changed the name of his company to the Crown Cork and Seal Company.

He founded in 1892 his own manufacturing business, the Bottle Seal Company, in Baltimore and approached not only soft drink manufacturers but also brewers.

Due to the almost immediate success of the Crown Cork he changed the name of his company to the Crown Cork and Seal Company.

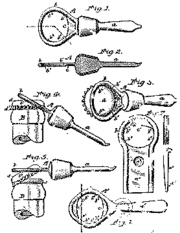

In 1894, he invented the essential tool to the crown cap: the bottle opener!

By 1898, he created a foot-powered crowner device which could fill and cap 24 bottles a minute for sale to bottlers and retailers so that they could seal the bottles with his caps quickly and easily.

By 1906, when he died, the Crown Cork and Seal Company had opened manufacturing plants in Brazil, France (Société du Bouchon Couronne), Germany, Japan, and the United Kingdom.

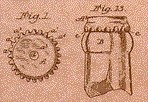

The first crown caps had 24 teeth, this number was reduced to 22 in 1903 and from 1911, the caps will have 21 teeth, the minimum required to maintain the seal.

This was guaranteed by the use of a natural cork disc inside the cap. Unfortunately, natural cork was not uniform and could have irregularities that could prevent a perfect seal.

This was guaranteed by the use of a natural cork disc inside the cap. Unfortunately, natural cork was not uniform and could have irregularities that could prevent a perfect seal.

This problem was solved from 1915 by the progressive use of composite cork which offered a regular surface.

For some drinks, including milk, a paper or aluminum disc was affixed to the cork so that it would not be in contact with the liquid.

From 1955, capsule manufacturers began to replace cork with plastic, but since plastic was more expensive, brewers where first to switch due to their larger production volume. Today, only plastic is used.